3 point bend test fixture|three point vs four bending : exporter 20 KN 3-Point and 4-Point Bend Fixture. Principle of Operation Suitable for both . WEBLearn how to get started with using WhatsApp. Your privacy and security are important. Learn how to stay safe on WhatsApp. Learn how to back up and restore your chat history. Learn more about information for teens on WhatsApp. Learn how to create and participate in communities. Learn about WhatsApp's business solutions and how to get started.

{plog:ftitle_list}

House Flip. 73,251 ratings. Strategy Games. Time Management Games.

3-point flexure fixture with an optional conversion kit for 4-point loading. Conforms to ISO, ASTM, DIN, and many other standards. Fully adjustable span distance to suit a wide range of .

spigen slim armor iphone 6 drop test

Three and four-point fatigue flexure fixtures allow a variety of flexural and fracture .20 KN 3-Point and 4-Point Bend Fixture. Principle of Operation Suitable for both .This family of bend fixtures is designed for 3-point and 4-point bend testing of plastics, metals, ceramics, tubing, and many other materials. Two base sizes are available, along with an upper .

three point vs four bending

Affordable three point bend fixtures for more unique applications. Loading edge and supports can be changed to optional parts or customized designs. The support and loading edges are constructed of alloy tool steel with reliable .Our TA238 flexural fixture allows 3 & 4 point bend testing to test properties of materials with 2.5 kN and 10 kN capacity. Request a quote today.

ADMET bend fixtures are configured for 3-point and 4-point bend testing and are available in a variety of force capacities, support types, and span lengths. Model selection is often based on the size of the test specimen, expected forces, and .Three and four-point fatigue flexure fixtures allow a variety of flexural and fracture toughness bond tests to be performed, including determination of flexural modulus, flexural strength and .The fixtures have adjustable spans with easy-to-use, permanently attached scales for equal positioning of the rollers. The hardened rollers ensure test result accuracy by reducing undesirable loading and frictional forces on the .Mark-10 family of bend fixtures is designed for 3-point and 4-point bend testing of plastics, metals, ceramics, tubing, and many other materials. Two base sizes are available, along with .

three point bending test setup

three point bend test formula

20 KN 3-Point and 4-Point Bend Fixture. Principle of Operation Suitable for both static and dynamic flexure testing, this bend fixture can be configured as either a 3 or 4 point (requires addition 2810-505) device.

ISO 178 is a test method for determining the flexural properties of rigid and semi-rigid plastics by performing a three-point bend test on a universal testing system. Back; Home; Products. Materials Testing. Universal Testing Systems. Automated Testing Systems . 3 Point Bend Fixture (2810-400) Deflectometer Plunger (2810-403) Strain .

Easy to install, the 3 point fixture can be modified with an optional conversion kit to provide a 4 point bending conversion. Lower anvils are adjustable to accommodate specimens of different spans. Deflection of the specimen can be measured either through crosshead displacement, or for more precise measurement use the mid span direct .

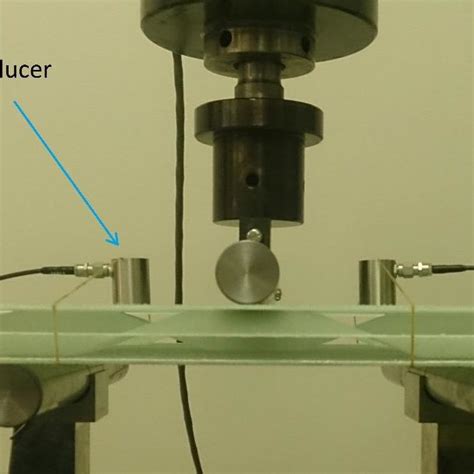

This flexure test fixture, shown in Figs. 1 and 2, is designed to test materials in both three- and four-point flexure. Prior to 1997, one ASTM Standard, i.e., ASTM D790, covered both loading modes. . -10 (2010), “Flexural Properties . The three-point bend test is standardized under ASTM D790 and ISO 178, ensuring consistency and reliability in the results. A standard test method in material testing provides a uniform framework for conducting tests, enabling the comparison of results across different studies and applications. . 3 point bend fixture with interchangable .3-point flexure test kit for small plate bending test on metallic mate‐ rials Distance gauge for standard compliant positioning of the flexure test kit PI 345 1223 Applications The VDA 238-100:2020-07 is the basis for the test arrangement. This 3-point flexure test kit is used to perform small plate bending tests for determination ofBend fixtures vary widely depending on the sample being tested, the forces required and the calculations being determined. Common fixtures are generally 3-point or 4-point, but others are available that can acommodate a wide range of capacities. Common parameters used to determine the appropriate bend/flex fixture are listed below.

3-Point and 4-Point Bend Fixture. Principle of Operation Suitable for both static and dynamic flexure testing, this bend fixture can be configured as either a 3 or 4 point (requires addition 2810-505) device. The specimen is supported on two lower anvils and the load is applied in the center of the specimen by either a single upper anvil or 2 upper anvils when used in a 4 point .4-Point Bend Fixture Conversion Kit (2810-605): Used to convert 2810-600 from a 3-point to a 4-point bend fixture, the 4-point bend conversion kit has a variable span of 5 - 40mm (0.19-1.57in) and is suitable for both static and dynamic testing. The test specimen is supported on two lower anvils while the load is evenly applied by two upper anvils.

The test uses a universal testing machine and a three point bend fixture to bend plastic test bars to acquire the data needed to make the calculations. The calculations and set-up for D790 are more complex and time consuming compared to other tests so please read the entire specification from ASTM before running the test. ISO-180 is similar in .This fixture can exert forces up to 250 kilonewtons (or 55,000 lbs). G103 3 Point Bend Fixture The G103 3 Point Bend Fixture is made for plastics with mid-ranged toughness. This bend fixture can exert up to 50 kilonewtons (or 11,250 lbs) of force to a specimen. G238 3 Point Bend Fixture The G238 3 Point Bend Fixture is made to bend test thinner .

These differences affect your test fixture choices, software calculations, and data analysis. Using our Newton controller, each test report can contain different data from one test sample to the next. 3-point bend tests are simpler to set up than 4-point and the bend fixtures are also more affordable. The 3-point test can provide accurate .The 3-point flexure test to ASTM D790 is a traditional standardized characterization method for rigid and semi-rigid plastics. The flexural properties determined with these tests are of great importance to designers, engineers and material manufacturers to ensure that the plastic material used meets the requirements for its intended application.This test setup includes a 3400 Series test system with a 3-point bend fixture and no extensometer, meaning that strain in this case must be measured by crosshead displacement (Type 1 testing). Whenever strain is measured via crosshead displacement, compliance correction is recommended, though not required. 3400 series test frames can also be .

W-6810 | Guided-Bend/Weld Bend Test Fixture. Guided-Bend / Weld Bend Test Fixture, Adjustable Span for "U" bend tests of plane plate or welded flat specimens. Fixture consists of a t-slot base with adjustable span supports supported by two tie rods. Fixture specifications: Span - 0 to 254 mm (10.0 in) Specimen width - up to 76 mm (3.0 in)

3 point bending test standard

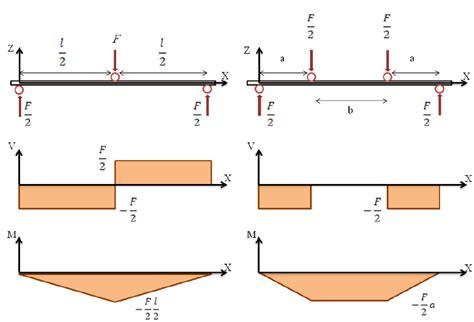

The three point bending fixture conforms to ASTM D790-17 & ASTM D7264/D7264M – 15 standards. Pipeline’s unique three point bend test setup is designed to hold the shaft under a light and constant axial tension at a set .The flexure fixture allows a variety of flexural and fracture toughness bond tests to be performed, including determination of flexural modulus, flexural strength and flexural yield strength. Easy to install, the 3-point fixture can be modified with .Bend fixtures are used with universal testing machines in order to determine the flexural properties, including flexural (bend) strength and flexural strain, of materials. ADMET bend fixtures are configured for 3-point and 4-point bend .In the 4-point bending test, the checking fixture differs from the 3-point bending test only in its test punch. Instead of the single punch applying force in the center, a double punch is used. There is a constant bending moment in the area between the two upper pressure points. Transverse forces do not occur in this area.

3.2 Fixtures, specimen positioning and CMOD installation Put the machine in standby mode via rotating the switch denoted by #4 (in Figure 1) to its leftmost position. With the help of the present supervisor, change the fixtures of the machine (#5 in Figure 1) and install the ones suitable for the three-point bending test, as demonstrated in .

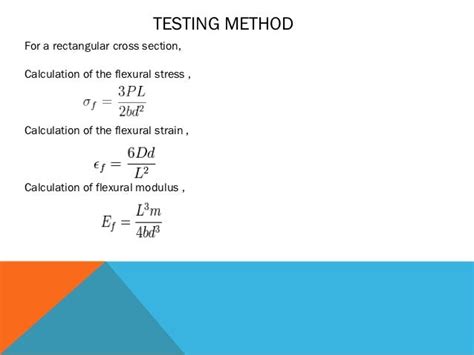

3 point & 4 point flexural bend test fixtures 50kN. 3 & 4 Point Bending Fixture - TA103 quantity. Add to cart. Add to quote. Description Additional information Downloads Description. TA103 Bending Fixture 50kN with wheel move the supports centric, for universal use. .The flexure fixture allows a variety of flexural and fracture toughness bond tests to be performed, including determination of flexural modulus, flexural strength and flexural yield strength. Easy to install, the 3-point fixture can be modified with an optional conversion kit to provide a 4-point bending conversion.This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a 3 point or 4 point bend fixture. The key analysis when performing bend testing are: Flexural Modulus – This measures the slope of a stress / strain curve and is an indication of a material’s stiffness;

3-Point and 4-Point Bend Fixture. Principle of Operation Suitable for both static and dynamic flexure testing, this bend fixture can be configured as either a 3 or 4 point (requires addition 2810-505) device. The specimen is supported on two lower anvils and the load is applied in the center of the specimen by either a single upper anvil or 2 upper anvils when used in a 4 point .3-point Bend Test Fixtures for Plastics. The radius of the punch and support points for the 3-point bend test fixture is specified in ASTM D790. Different radius values for punches and supports are required for different thickness specimens. Therefore, choosing the optimal test fixture for a given specimen is essential.The mini flexure fixture is designed for 3-point bend or flexure testing of smaller components and specimens, where the specimen is supported on two lower anvils and the load is applied by a single or optional dual upper anvil. . When a 3-point bend test is done on a brittle material like ceramic or concrete, flexural strength is often called .The flexure fixture allows a variety of flexural and fracture toughness bond tests to be performed, including determination of flexural modulus, flexural strength and flexural yield strength. Easy to install, the 3-point fixture can be modified with an optional conversion kit to provide a 4-point bending conversion.

ISO 14130 is another standard for flexural testing of plastics and composites using a 3-point bend fixture, with specific requirements for specimen preparation, test conditions, and data analysis. ASTM D7264 is a standard test method for flexural properties of polymer matrix composites using a 3-point bend fixture.

3 point bending test procedure

10 de dez. de 2022 · O sábado (10) promete com jogos de fortes emoções na Copa do Mundo 2022! Depois de Marrocos X Portugal , Inglaterra e França são as seleções que .

3 point bend test fixture|three point vs four bending